Starting with some 2 x 2 cedar, a foam ‘dummy’ Chrysler 426 block and components - The wood is replaced with 1 3/4” x 1/4’ wall DOM steel tubing - ‘We can see and feel as it coaleses in the ether’

An assembly jig from a giant section of steel ‘I’ beam with rolling casters that guarantees plumbosity and straightistickness

the front suspension arms were fabricated from 1/4” steel plate

super strong box sections !

Frog wanted a single front wheel - this is my version of ‘Center hub steering’

Compare the original wooden model, built to get our minds around the concept - - “Generally I’ll wake up in the middle of the night, run over to the shop and knock something out to ‘capture’ the thought before it evaporates”

FROG’S BUILD

Frog came up from So-Cal’ on a regular basis to check progress, fondle the parts and brainstorm the next phase

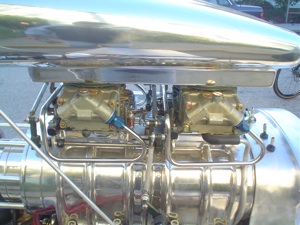

The new ‘426’ Chrysler Engine was purpose built by legendary Hemi builder John Arrusa out of Carolina for this project - Slightly de-tuned for the street, twin plug Hemi with 8/71 GMC - 1000 HP blower motor runs perfect, smooth and strong

With Baer rotor and six puck caliper

Mikey Lamassa and John Jimelli check out progress

-

-hard hat area -

- web page in progress -

Bandsawn prototype wood suspension arms expedite the developement process

The front wheel was machined from an 800 lb block of billet aluminum - 760 pounds of aluminum chips were machined off to create a 40 lb finished wheel - two 24” Metzler motorcycle tires are mounted on one wheel

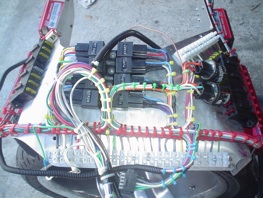

Dave ‘TAZ’ Nelson handles the electrical and plumbing chores - I can accept perfrction - Thanks Taz !

A ‘Saddle’ that straddles the fuel cell and steering gears is a modular unit with all essential electrical components

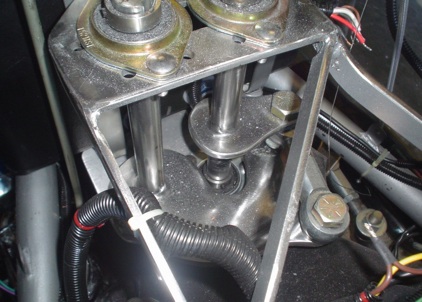

Eight separate trys over an eight month period to get the steering right - basic Archimedian leverage principles, racing go-cart bearings and hot rod heim ends finally did the trick

Pleasanton Ca.

A Leverage Advantage was needed for the ‘Handlebar to Draglink’ System

don’t let your meat loaf !